So, which of the many schools of thought or potential process improvements deliver high ROIs in typical hardware development systems? Well, according to our analyses, in most companies, the big two process improvements with the highest ROI are Visual Work Management and Project Risk Management.

If you have the right tools for Visual Work Management and Project Risk Management, the ROIs in these areas are exceedingly high - easily over one hundred, and often over one thousand times the cost – when considering the Cost of Delay (lost profit due to being late to market). If you have the best VWM tools and methods available for your type of development system, you can solve a lot of these problems and go a lot faster with relatively little cost and effort. Watch a demonstration of Playbook Lean visual management software to take a deeper dive into the benefits of the right visual management tool.

Download the complete guide to Lean and Agile product development.

I buy a lot of books—more than I have time to read. So if it’s a “good” book, I’ll actually finish it. If it’s a “really good” book it will have ideas in it that I’ll want to find later, so I’ll mark those pages with a piece of sticky note. Most of the really good books get just a few pages marked. However, Managing the Design Factory (MD), by Don Reinertsen, has forty-six notes in it…! There got to be so many pages marked that I started putting the stickies on the side of the page so I could tell the new ones from the old ones.

There is another that actually beats it in terms of density. Don Reinertsen’s third book is called The Principles of Product Development Flow: Second Generation Lean Product Development. Thankfully, you won't need to put sticky notes in it because he organized into eight sections with 175 numbered principles.

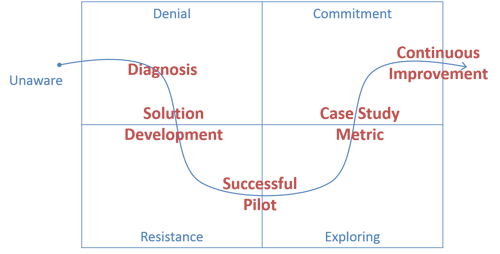

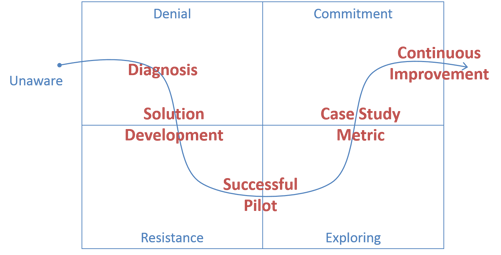

To get started, let’s review the solution steps in the phases of change diagram.

It should be clear that you need to have a successful pilot that yields measurable business results in order to prove its effectiveness and continue with the next initiative. But what the diagram doesn’t show is what’s necessary within the pilot to create those results.

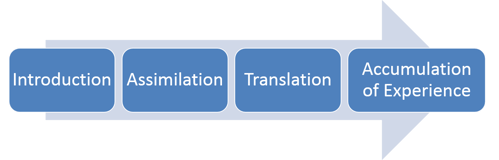

Fortunately, there’s a model that makes this process easier to understand. It comes from the Kirkpatrick model for evaluating training effectiveness and is outlined in the image below.

If you view it backwards (from right to left), it shows that in order to get results, you need to change behavior. And in order to change behavior, people need to learn something. And finally, in order to learn something, people need to have a good reaction to the training.

This should sound logical, but there’s a hidden stumbling block.

Interested in understanding more Lean-Agile Principles? Check out our free Lean-Agile training on Playbook Academy such as Rolling-Wave Planning, Applying Agile to Hardware and Critical Chain Project Management.

Think about that. Have you ever seen people go to training and come back excited, but a few weeks later, there’s no evidence of any change?

It’s actually quite common. There’s a reason most training doesn’t work, but it’s not because it was “bad training."

There’s a good solution for this that we learned from a book written by Charles Fred called, Breakaway: Deliver value to your customers—fast!

In it Mr. Fred describes the four phases of learning:

Most companies stop with step two—they send someone to a general class. Some training programs go to step three and teach the students how to apply the knowledge at work.

But very few companies go to step four and actually coach, or otherwise enable, the students in the new behavior until they have reached proficiency.

That’s too bad because Charles Fred makes it clear:

The amount of practice it takes for new experiences to become habit depends on a lot of things:

Basically, the higher the “benefit to cost ratio,” the quicker people will adopt new behaviors. But people still have to get to a certain amount of time to practice the new behavior before you can expect it to stick.

Let’s review the solution phases laid out on the phases of change diagram again.

In order to ensure success on your first initiative, you must follow four key steps:

If you do those things right the first time, you will have broken the cultural barrier and set your company on the path for continuous improvement!

Interested in Learning more about lean product development?

We have a series of webinars dedicated to Lean product development training.

Guide to Lean Project Management

Science and economics behind “failing fast”

Lean Product Development the Opportunity of the Century

Lean Product Development Case Study

Principles of Lean Product Development

Lean Product Development Value Chain

Get started with Lean Product Development

Lean Product Development: Cultural Resistance

4 ways to Ensure Your Lean product Development Initiative Won't Fail

Guide to Kanban

Guide to Visual Work Management

Address

PO Box 18027

Boulder, CO 80308

303-323-4296

info@accuer.com

Lean Project Management

Lean Product Development

Agile Development