Great teams deliver great products. To win the game of product development, you need methods that inspire team thinking and teams that know how to execute them. Critical chain project management is one of these "team" methods. Find out how critical chain helps product development teams work together, better.

What is critical chain project management?

Critical chain project management is a method of planning and managing projects that focuses on the resources (people, equipment, physical space) required to execute project tasks. It was developed in 1997 by Eliyahu M. Goldratt. The basic idea is that a system’s throughput is determined by the weakest performer, called the constraint. Critical chain project management seeks to identify the constraint and then optimize the system based on that constraint.

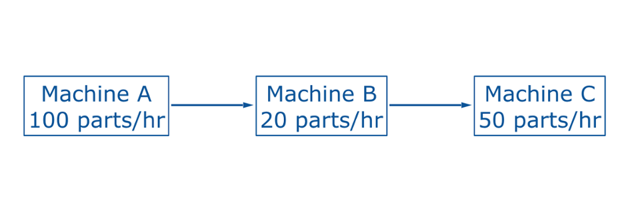

For example, in the image below we see three machines A, B and C in a serial process.

The maximum number of parts that this serial process can produce is determined by the machine with the lowest capacity. In this example, Machine B is the constraint and therefore the production line’s maximum throughput is 20 parts/hour.

5 Steps to Critical Chain Project Management

- Identify the constraint

- Exploit or make full use of the constraint

- Subordinate all other system elements to the constraint

- Elevate the constraint

- Rinse and repeat - it’s a continuous process of tweaking to optimize the system

Let us explore each of these points a bit further.

1. Identify the constraint. See example above.

In the product development system the constraint is people, not machines. However the constraint is not all the people, but specifically those people working on critical chain tasks (critical resources).

2. Exploit or make full use of the constraint

Making full use of the constraint means ensuring the critical resource has clear priorities and focuses 100% on the critical task at hand (single-task not multitask). This includes a conscious effort by managers to take low priority meetings off their plate as well as a conscious effort by the team to minimize casual interruptions (“Hey, did you see the game last night?” ;-) ).

3. Subordinate all other system elements

Everyone on the team finds ways to support the critical resource and help them get their work done. If you can help the critical resource, you should put your work aside and do so. Make sure the critical resource has everything they need and if the critical resource needs inputs from you (e.g. material specification, test results, dimensions etc.) put your work aside and ensure that what you provide them is complete and accurate. In other words, take the time to make sure we avoid unnecessary rework on the critical chain. In critical chain project management we don’t sacrifice quality, quality is a must!

4. Elevate the constraint

Typically, when team members think about elevating the constraint, they think of adding resources. However, typically there is a quicker, cheaper opportunity - be more resourceful. For example, perhaps the work on the critical chain can be decomposed into pieces – some that must be done by the critical resource and others that can be handed off to others.

Shared project buffers vs. individual task buffers

Another principle we recommend is using shared project buffers instead of individual task buffers. We’ve written about this extensively here. Shared project buffers encourages a team spirit and approach. Everyone owns the shared project buffer and everyone is responsible for managing its use effectively.

Conclusion

In summary, you can see the benefits of critical chain project management. It inspires a team approach with everyone working together to ensure the success of each individual when they are critical resources which ensures the success of the project and therefore the team. Together, everyone wins the game of product development!

Want to share the benefits of critical chain project management with your team? Download the PowerPoint presentation.

Related articles

What is Critical Chain Project Management

The Benefits of Kanban and Gantt for Hardware Development

A Guide to Kanban Boards

Seven Benefits of Visual Management

Visual Management Boards

Resource Loading

Resource Leveling

Guide to Lean Project Management

Guide to Lean Product Development